All may pages

CSE - Customised Search Engine - Conversations on Innovations

Where my visitors live

InnoCentive: Challenges-All Categories

IdeaConnection :: Idea Contests

EUROPA - Research and Innovation - What's New

EUROPA - Research and Innovation: What's New in Innovation

Friday, June 25, 2010

This-Above-All: Walking works, is good for your health and for business -Universities and CollegesTop brains look at Sustainability_EAUC Confs

Publié par Unknown à 12:32 am 0 commentaires

Thursday, June 24, 2010

Materials Science and Engineering Defined: Environmental Association of Universities and Colleges-Top Brains look at Sustainability_Some Materials Aspects

Publié par Unknown à 11:48 pm 0 commentaires

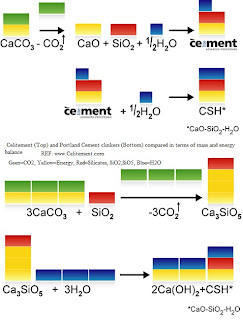

New Green Construction Material Innovation_Low energy cement production by Celitement via IOM3: The Global Network for Materials, Minerals & Mining Professionals

"Low energy cement production

Researchers in Germany have developed a high-performance mineral binder, which, they say, can help reduce the energy consumption and CO2 emissions associated with cement production.

Celitement, the material’s trade name, is based on hydraulic calcium hydrosilicates."

Celitement is made by forming calcium silicate hydrates in a hydrothermal reaction at temperatures between 150 and 200ºC. In a second step the autoclaved material is co-milled with a SiO2-rich material, such as quartz-sand.

‘Production of Ordinary Portland Cement (OPC) at temperatures of up to 1,450°C is a highly energy-consuming process,’ explains Dr Hanns-Günther Mayer, Managing Director of Celitement, a spin-out of the Karlsruhe Institute of Technology (KIT). ‘In addition, cement plants emit more than two billion tonnes of CO2 annually (2x10^9 tonnes CO2). In comparison to OPC Celitement has the potential to reduce both energy use and CO2 by up to 50%.’

‘During hydration, Celitement transforms to calcium silicate hydrate gel. This material is the cement hydrate, which defines the mechanical strength and stability of traditional concrete. Thus material properties of test samples made with Celitement, such as strength development and final compressive strength (up to 80 MPa) resemble those of samples made with OPC,’ adds Mayer.

Scale-UpStrength can be regulated by varying the mixing and processingparameters. ‘One big advantage of Celitement is the fact that it can be used just like any other cement.’

In spring 2011, a small pilot with a production rate of 100kg/day will start operation at KIT to perform extensive material tests and prepare scale-up.

More on Celitement

RELATED POSTS:

Materials and Environment-Embodied Energy of Materials

Nanoengineered concrete R & D to cut CO2 emissions (Feb 08, 2008)

WEDGE-A-WAR follows from Theory to Practice (Oct. 18, 2006)

Publié par Unknown à 6:52 pm 0 commentaires

Libellés : "Wedge a War", cement, CO2, concrete, energy, Environment, GHG, Green-Construction-Materials

Saturday, June 05, 2010

Re-inventing the wheel? Inconsistent results? Failure to push all the way through and LEGISLATE?

Original title and full article , 3rd June,COLOGNE from The Economist print edition with pertinent comments, all online in the Science &Technology pages, cf ref. 1 below.

"Cleaner diesel engines

Pouring water on troubled oils To make engines cleaner, add H2O," (an old idea)

Motivation for action

"Research by James Corbett of the University of Delaware estimates that soot from ships’ diesels contributes to 60,000 deaths from heart and lung disease every year."

The problem

Water & Oil do not mix naturally.

Solution

The current innovative solution reported in The Economist is due to Reinhard Strey of the University of Cologne. He uses surfactants- to a class of chemical substances which, usually in small quantities, modify the interfacial tension existing between different substances, here, H20 and Oil. Dish washing liquids are the best known household surfactants which work in this principle. removing oil and grease from our dinner plate.

Apparently many attempts to improve combustion using water and surfactants failed.

Now, Dr Strey after extensive research eventually lighted on a mixture of oleic acid (a fatty acid found in various vegetable oils) and nitrogen-containing compounds called amines. This mixture dissolves readily in diesel fuel and binds water to it without any need for stirring. The water droplets themselves can be as small as a nanometre (a billionth of a metre) across. That they are so small helps stabilise the emulsion.

A very important feature of this invention, worth repeating, is that the emulsion created is stable. The result it is claimed is, in effect, a liquid sponge, and means the mixture can be stored indefinitely, like ordinary diesel, without risk of separation.

When the Oil-Surfactant-H2O emulsion is burned, is the near-complete abolition of soot, and a reduction of up to 80% in nitrogen-oxide emissions. The surfactant itself also burns without creating emissions beyond water, carbon dioxide and nitrogen.

The next stage is to test the mixture in the real world. MTU, a German engine-builder, (Germany's Rolls-Royce) is now looking into the matter.

Will this innovation be adopted and made law on The Seas or is this just more Eau de Cologne to mask the stink?

REFERENCE:

The Economist, 3rd of June 2010 Science & Technology

Publié par Unknown à 9:10 pm 0 commentaires

Libellés : Clean Technologies, Combustion, Innovations, Innvention