"Low energy cement production

Researchers in Germany have developed a high-performance mineral binder, which, they say, can help reduce the energy consumption and CO2 emissions associated with cement production.

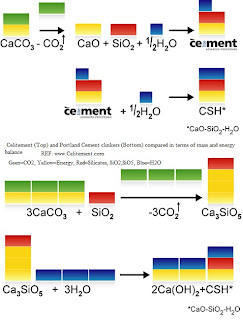

Celitement, the material’s trade name, is based on hydraulic calcium hydrosilicates."

Energy Saving

Celitement is made by forming calcium silicate hydrates in a hydrothermal reaction at temperatures between 150 and 200ºC. In a second step the autoclaved material is co-milled with a SiO2-rich material, such as quartz-sand.

‘Production of Ordinary Portland Cement (OPC) at temperatures of up to 1,450°C is a highly energy-consuming process,’ explains Dr Hanns-Günther Mayer, Managing Director of Celitement, a spin-out of the Karlsruhe Institute of Technology (KIT). ‘In addition, cement plants emit more than two billion tonnes of CO2 annually (2x10^9 tonnes CO2). In comparison to OPC Celitement has the potential to reduce both energy use and CO2 by up to 50%.’

Materials Strength:

‘During hydration, Celitement transforms to calcium silicate hydrate gel. This material is the cement hydrate, which defines the mechanical strength and stability of traditional concrete. Thus material properties of test samples made with Celitement, such as strength development and final compressive strength (up to 80 MPa) resemble those of samples made with OPC,’ adds Mayer.

Scale-UpStrength can be regulated by varying the mixing and processingparameters. ‘One big advantage of Celitement is the fact that it can be used just like any other cement.’

In spring 2011, a small pilot with a production rate of 100kg/day will start operation at KIT to perform extensive material tests and prepare scale-up.

REFERENCE:

Low energy cement production | IOM3: The Global Network for Materials, Minerals & Mining Professionals

0 commentaires:

Post a Comment